Recycling machines for EPS/EPP

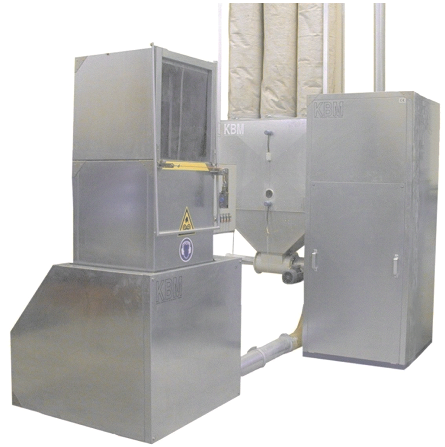

KBM recycling systems transform your scrap back into reusable individual beads - ready to be brought back into production.

The recycling systems are usable for EPS (Styropor/Styrofoam), EPE, EPP, Arcel, Neopor and similar materials.

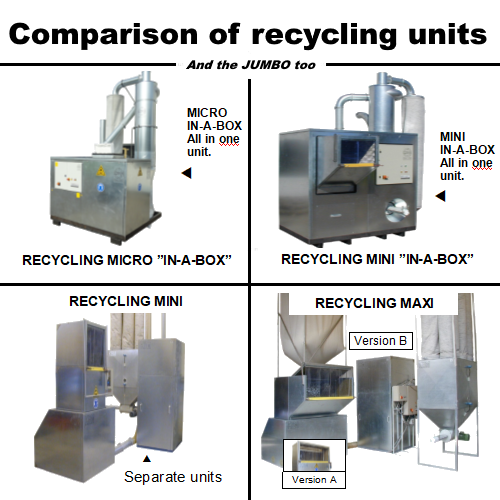

Recycling machinery for your specific needs

KBM offers a wide arrange of recycling machinery - suitable for your specific needs. Every product with further description and technical assets are listed within the individual recycling machinery product pages.

Benefits of choosing KBM recycling machinery:

- Very low dust creation

- Separates down to the individual bead

- Perfect de-dusting results

- High quality units produced in Denmark