Response

within one working day

Quality

produced in Denmark

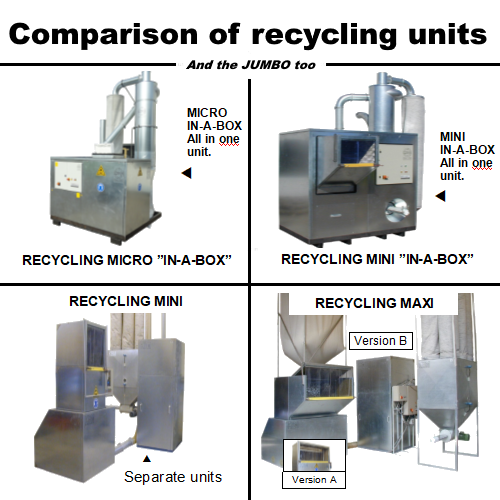

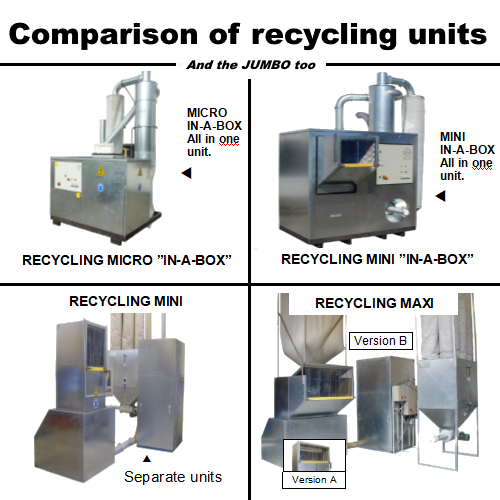

Comparison of recycling units

Overview comparison of the KBM recycling units.

within one working day

produced in Denmark

Overview comparison of the KBM recycling units.

For a technical comparison, click the "Technical Data" tab. For leaflet download, click the "Data Sheet" button to the right or by clicking here. Each unit is extendedly explained on their own product page.

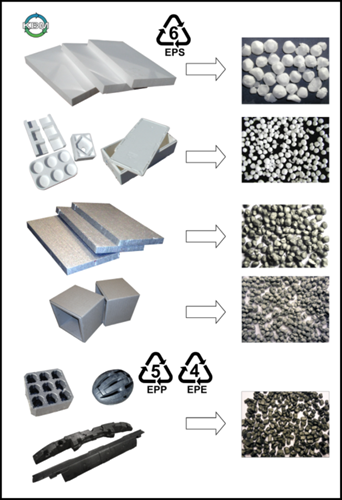

The only way to make money on recycling of EPS and EPP is to reuse it as EPS or EPP, where the value correspond to the price of new EPS or EPP beads. The recycled EPS and EPP material can be reused in shape moulding production in a ration of at least 10-20 percent without any perceptible optical or physical change of the product quality. For block moulding 20-50 percent can be added.

Due to the fact that the material is broken down to the individual bead size similar to the new beads, it is homogeneous with the new pre-expanded beads and consequently de-mixing problems in the silos causing uneven density distribution are minimized. Problems like blocking of core vents due to dust and lumps of material causing hot wire cutting problems in terms of inaccurate sheets with bad surface are also minimized.

Thanks to the two step/double chamber system and the large screen surface and granulation chamber the recycling plants produce from waste production, cut-offs from block production or even from used EPS and EPP/EPE mouldings, a high quality recycled material, which contains a minimum of dust.

We developed the completely integrated recycling concept for reusing EPS material in 1978 and have in the past supplied more than 350 complete recycling plants world-wide, where they have solved the recycling problems and brought substantial savings to our customers. Our experience in this field enables us to solve the problem of reusing the waste material with optimal result for both EPS, EPP, EPE, Arcel, and Neopor for shape- and block-moulders.

At KBM we offer 5 different systems for your recycling needs (click on a product name to continue to the respective product page);

Micro In-A-Box, Mini In-A-Box, MINI, MAXI, and JUMBO.

|

Different EPS, EPP and EPE material to beads |

|

Four different recycling units. Others are the JUMBO recycling, pre-crushers, dust compactors and de-dusters |

TECHNICAL OVERVIEW OF THE DIFFERENT KBM RECYCLING MACHINES

| The specifications for all recycling systems are given by recycling EPS | MICRO IN-A-BOX | MINI IN-A-BOX | MINI | MAXI | JUMBO |

Capacity

| Granulated and dedusted EPS material (shape) (6mm screen) 2) | 2-3 m3/h 70-105 ft3/h |

6-8 m3/h 210-280 ft3/h |

6-8 m3/h 210-280 ft3/h |

10-12 m3/h 350-420 ft3/h |

15-20 m3/h 525-700 ft3/h |

| Granulated and dedusted EPS material (block) (10mm screen) 2) | 4-6 m3/h 140-210 ft3/h |

9-10 m3/h 315-350 ft3/h |

9-10 m3/h 315-350 ft3/h |

18-20 m3/h 630-700 ft3/h |

35-40 m3/h 1225-1400 ft3/h |

| Granulated and dedusted EPP material | 20-50 kg/h 44-110 Lbs/h |

60-100 kg/h 130-220 Lbs/h |

60-100 kg/h 130-220 Lbs/h |

100-160 kg/h 220-350 Lbs/h |

1) |

Measurements

| Hopper opening: Pre-crusher/granulator | 780 x 400mm 30" x 15" |

900 x 600mm 36" x 24" |

900 x 600mm 36" x 24" |

1400 x 600mm 56" x 24" |

1800 x 800mm 3) 72" x 31" 3) |

| Granulator screen surface | 0,2 m2 2 ft2 |

0,9 m2 9,7 ft2 |

0,9 m2 9,7 ft2 |

1,4 m2 15 ft2 |

2,4 m2 26 ft2 |

| Floor space (depending on the setup) | 4 m2 42 ft2 |

6 m2 65 ft2 |

12 m2 120 ft2 |

16 m2 160 ft2 |

40 m2 400 ft2 |

Electrical load

| Total for standard EPS (approx.) | 11,5kW | 19kW | 19kW | 36kW | 57kW |

The KBM Micro In-A-Box is a Plug & Play unit - easy to install. It is a complete recycling system in one…

Read more

The KBM Mini recycling system is a complete recycling machine for small and medium moulding operations. The…

Read more

The KBM Mini In-A-Box is a Plug & Play unit - easy to install! It is a complete recycling system in one …

Read more

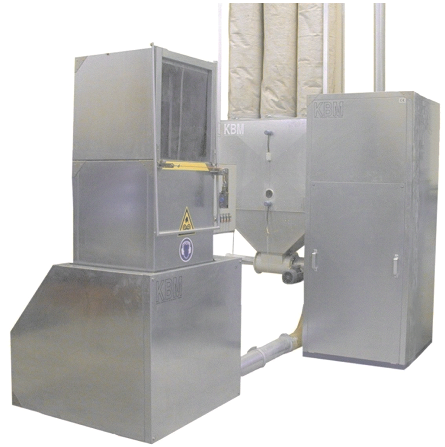

The KBM Maxi is a complete recycling system for large moulding operations. The Maxi recycling system can ru…

Read more

The KBM Jumbo is a complete recycling system for very large moulding operations. The Jumbo recycling system…

Read more

Individual pre-crushers secure flexible and fast pre-handling of material.

Read more

The KBM Dust Compactors reduce the volume of material dust 20-30 times - as well as reduce the cost of your …

Read more

Individual de-dusting units allow you to clean the material after a granulator or pre-crusher.

Read more