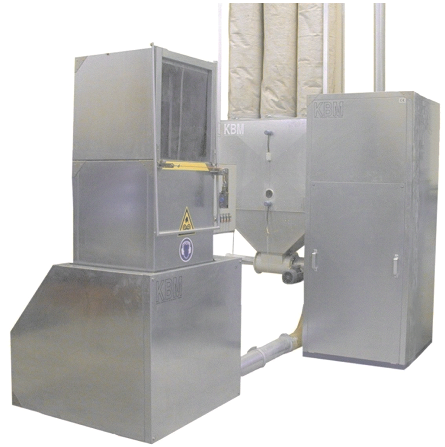

ALL IN ONE BOX!

This machine is a complete recycling system built into one cabinet; pre-crusher, granulator, de-duster, and transport blowers, to recycle your scrap from the production. Dust is collected in a bag or optionally a dust compactor. Whole pieces are pre-crushed and granulated into individual beads, the dust is separated, the beads are conveyed to a storage silo and the extracted dust is compacted.

The Mini In-A-Box is for you...

... if you need to treat particle foam pieces, so they can be recycled back into a production of new products. Perfect for the medium moulder or the moulder who has a medium production of other material (or colour) that should not be mixed with the general production.

The KBM In-A-Box units are the only systems on the market, where you have a pre-crusher / granulator, a dust separation unit, a cyclone venting, and a dust compactor built into one unit. This units can be supplied both with or without a dust compactor, as well as the optional external pre-crusher for high-speed pre-crushing to reduce labour costs by reducing the hours required to feed the unit.

Due to the unique KBM design of the granulator, only 5-7% EPS dust is generated by granulating to individual beads. The very little dust generated (which is removed) and the final product can be used to mix into a production again to replace beads of new material. The very efficient dust separation ensures that there is no production stops afterwards due to problems with blocked core vents. The unique low-maintenance cyclone venting system which ensures that you have sufficient venting for a good dust separation without a lot of venting bags to clean.

Measurements and qualities

The Mini In-A-Box unit is available in a standard version for material up to 30-40 Kg/M3 (2.2-2.5 lbs/cf) density, and a high-density (HD) version for material of higher density.

It can easily be moved around by a forklift or similar. Further, the outer parts can be taken off in a very short time and the recycling box can now be put in a truck or into a standard container for easy transportation.

You can gain economical benefits from replacing new raw material with recycled beads as you gain up to 85-95 % of the original value of the raw material. Using one of the KBM In-A-Box units allows for high rates of reusability. 10-20% of new material can be replaced by recycled beads in shape moulding (and even more when using a KBM Styromix), and 20-50% or even 100% in block moulding - depending on the equipment available to mould.