Response

within one working day

Quality

produced in Denmark

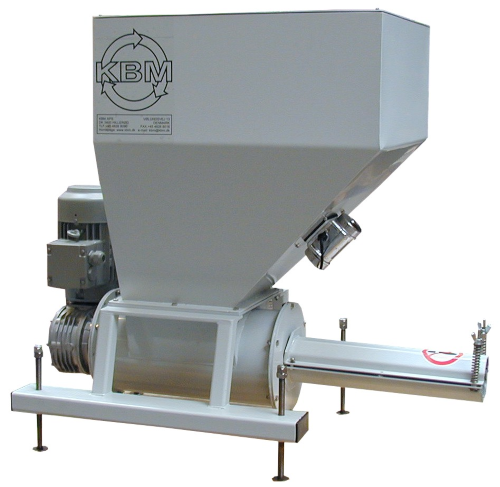

Dust compactors

The KBM Dust Compactors reduce the volume of material dust 20-30 times - as well as reduce the cost of your dust disposal.

within one working day

produced in Denmark

The KBM Dust Compactors reduce the volume of material dust 20-30 times - as well as reduce the cost of your dust disposal.

The KBM dust compactors offer many advantages to the production in terms of easy handling of dust from EPS, EPP, EPE, Arcel or Neopor. It improves the surroundings of the dust handling location in the production, as no dust is flying around since there are no change of bags, compared to using plastic bags for collection.

The dust compactor is used to reduce the volume of dust 20-30 times, as well as reduce the costs of the dust disposal.

The basic dust compactor is available in four different sizes: MINI, MAXI, JUMBO, and GIGANT. It can be used in a large number of ways and be combined with any production line where dust occurs.

The basic KBM dust compactor can be equipped for multiple applications.

The dust compactors are also part of our large program of recycling plants and equipment for the EPS/EPP/EPE/ARCEL/NEOPOR foam industries.

Please do not hesitate to contact us for a discussion about how the dust compactors can be combined with your existing production line.

|

MAXI Dust Compactor with filter bags (venting) and small storage silo |

|

Dust Compactor with cyclone venting (no filter bags) |

|

Dust-O-Pactor Dust Compactor with closed filter bag venting |

|

Dust-O-Pactor Dust Compactor with closed filter bag venting (with double venting capacity) |

|

Cyclone Venting with dust conveyor blower (no compactor) |

|

Dust-Flex MAXI Flexible Dust Compactor with a small silo to be filled manually - no conveying by air Available with wheels or legs |

|

Dust-Flex JUMBO Flexible Dust Compactor with a small silo to be filled manually - no conveying by air Available with wheels or legs |

(Measured with EPS dust)

| MINI dust compactor | 0.75-1 m3 | 25-35 ft3 |

| MAXI dust compactor | 1-1.5 m3 | 35-50 ft3 |

| JUMBO dust compactor | 1.5-3 m3 | 50-100 ft3 |

| GIGANT dust compactor | 9-14 m3 | 315-490 ft3 |

(Experienced with EPS dust from a KBM recycling system)

Capacity measured in weight is depending on the volume capacity given above

| MINI dust compactor | 100m x 100m | 4" x 4" |

| MAXI dust compactor | 100m x 100m | 4" x 4" |

| JUMBO dust compactor | 150m x 150m | 6" x 6" |

| GIGANT dust compactor | 270m x 270m | 11" x 11" |

| Space required (most installations) | ca. 2-5 m2 | 20-50 ft2 |

| MINI with venting bags | 1.5m x 0.5m x 5.1m | 59" x 20" x 201" |

| MAXI with venting bags | 1.5m x 1.0m x 5.1m | 59" x 40" x 201" |

| MAXI with cyclone venting | 1.2m x 1.2m x 4.8m | 48" x 48" x 189" |

| JUMBO with cyclone venting | 1.2m x 1.2m x 5.4m | 48" x 48" x 213" |

| DUST-FLEX MAXI | 1.3m x 0.6m x 1.3m | 51" x 24" x 51" |

| DUST-FLEX JUMBO | 1.9m x 0.6m x 1.3m | 75" x 24" x 51" |

| Pipe connections: MINI or MAXI dust compactors | 160mm | 6" |

| Pipe connections: JUMBO dust compactors | 200mm | 8" |

| EPS | EPP | |

| MINI dust compactor | 1.5 Kw | 1.5 Kw |

| MAXI dust compactor | 2.2 Kw | 2.2 Kw |

| JUMBO dust compactor | 4.0 Kw | 4.0 Kw |

| GIGANT dust compactor | 7.5 Kw | 7.5 Kw |

| Voltage | 3x400V/50Hz, 3x480V/60Hz or other voltages | 3x400V/50Hz, 3x480V/60Hz or other voltages |

Individual pre-crushers secure flexible and fast pre-handling of material.

Read more

Individual de-dusting units allow you to clean the material after a granulator or pre-crusher.

Read more

The KBM Micro In-A-Box is a Plug & Play unit - easy to install. It is a complete recycling system in one…

Read more